Product Type:Nut & Seed Oil

Processing Type:Refined

Cultivation Type:Organic

Use:Season

Packaging:Glass Bottle, Bulk, Can (Tinned), Drum, Gift Packing, Mason Jar, Plastic Bottle, Vacuum Pack

Purity (%):99.9

Volume (L):1

Grade:A

Refined Type:Fractionated Oil

Place of Origin:Uthai Thani, Thailand

Brand Name:SUNFLOWER OIL

Model Number:ISO-1076

Refined Sun Flower Oil 100% Thailand Refined Sunflower oil

Raw materials:It is suitable to kinds of raw materials , such as sesame, sunflower seeds, soybean, peanut, coconut, etc

Raw material

Pretreatment Applicable oil: soybean, rice bran, sunflower, rapeseed, cottonseed, walnuts, corn germ, peanuts, copra, castor bean, palm kernel, palm nuts, sesame, olive and the like.

Working priciple

Working priciple

When the oil press is running, the processed material embryo enters the squeezing chamber from the hopper. The helix of the squeezed screw is pushed in and squeezed. The material embryo is carried out in the pressing chamber of the oil press. Under the condition of high pressure, there is a great friction resistance between the material embryo and the squeezing and squeezing chamber. The heat caused by the heat caused the thermal denaturation of the protein in the embryo, destroyed the colloid, increased the plasticity, and also reduced the viscosity of the oil and thus precipitated oil easily. The oil production rate of the oil press is improved.

Advantage

1) Simple structure ,easy in installation and maintation. 2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts. 3) Running in a high automatization and intellectualization,no pollution 4) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine . 5) Suitable to losts raw materials such as peanut, sunflower seeds, black seeds, olive, coconut, flax seeds, etc.

Product Specification

Product Specification

| Model | Capacity | oil content in cake | Motor power(kw) |

| 202 | 40-50 TPD | less than 13% | 30 |

| 204 | 75-80TPD | 15-18% | 30 |

| LYZX24 | 20-25TPD | 10-19% | 30+5.5+3 |

| LYZX28 | 40-60TPD | 15-19% | 45+11+1.5 |

| LYZX32 | 80-100TPD | 15-19% | 90+.5+1.5 |

| LYZX34 | 150-180TPD | 11-15% | 160 |

| SYZX12 | 4-6TPD | 4-6.5% | 18.5+1.1 |

| SYZX24 | Hot pressing 80-100 TPD | 10-17% | 55+7.5 |

| Cold pressing 40-50 TPD | 5-7% |

Company Profile

1.We have successfully obtained 27 national patents (including 8 invention patents), 6 international awards, 4 national awards and 2 provincial awards.2.We have the most complete production certificates of oil machines, such as “Design license of pressure vessel”,”Manufacture license of pressure vessel”,”Design license of pressure pipeline”,”Installation,reconstruction and maintenance license of pressure pipeline”, “Manufacture license of organic heat carrier furnace” and installation certification of mechanical and electrical equipment”.3. We are outstanding member enterprise of CCOA (Chinese Cereals and Oils Association), so we produce machines according to standard, and refined oil reaches the best edible oil standard.4.We have strong R & D team, production team and installation team, offer perfect after-sale service, after delivering goods, we will dispatch technicians to instruct installation, commissioning and train your workers to operate machines by yourselves.5.We are provincial enterprise abiding by contracts and keeping promises, we have produced oil machines for 65 years, with rich experience and own brand, so we are responsible for all of our projects, especially for oversea projects.6.Overseas projects: we are establishing every perfect overseas sample project all over the world, such as Russia,Kazakhstan,Uzbekistan,Tajikistan, Bolivia, Peru, Indonesia, Bangladesh, Thailand, the Philippines, Myanmar, Egypt, Sudan, Nigeria, Rwanda, Tanzania, etc.Our company can provide you with 10 to 25 kilograms (test equipment), 2 to 1,000 tons / day of oil refining projects , QiGroup naturally is your preferred partner for different oil quality. in Henan Huatai here are different options, batch chemical refining, semi-continuous physical refining, continuous physical refining program, where Henan Huatai provide you with the design (process, civil, electrical), manufacturing, installation, commissioning, training of technical personnel to the sale a full-service; advanced automatic control system to ensure that the entire production line of automatic, smooth operation; heat saving each segment to ensure that the processing costs to a minimum.

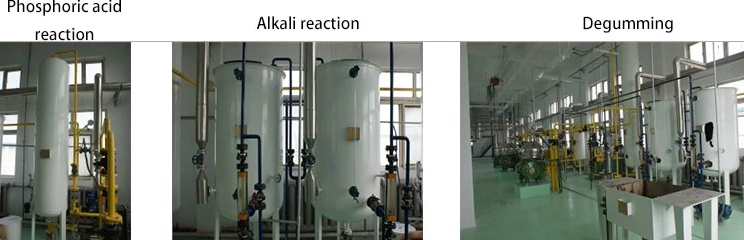

The main refining plant processes: degumming, dehydration, bleaching, deacidification, deodorization, dewaxing, degreasing. Crude oil in squeeze, extraction crude oil can be obtained national quality standards of edible oil through

Service

Our company always put the interests and quality of its clients first, insists the principle that there is no best but only better service. We will commit to provide quality products and improve on-site service and service after selling. Specific commitments are now as follows:We will organize an experienced engineering team, managed by the Project Manager.Ensure high-quality materials, excellent service provided to the user;During the installation process, we will appoint a technical and installation supervision services at the scene.We do debugging of stand-alone equipment and on-line debugging and commissioning test run to ensure normal operation of the project at full load conditions.Supply the technical of your staff to ensure training of personnel to operate independently for free.To ensure that once installation acceptance; Within one month, to provide customers with qualified acceptance after completion of archive.To ensure timely provision of equipment and accessories;We have developed new products, new technology, will give priority to customers;In the equipment’s warranty period (within 12 months of the date of commissioning qualified):Due to the quality of the equipment itself damage, we will repair or replace parts.Damage due to customer reasons, only charge the material cost for repair or replacement by the buyer. After the customer informed our company, we will put forward a propose within 24 hours, using the fastest way to resolve the issue the required components.We are willing to supply good service on your business development.

FAQ

QHow can I get the sample to check your quality?AAfter price confirmation, you can require for samples to check our product’s quality.QWhat can I get the price?AWe usually quote within 2 hours after we get your inquiry. If you are very urgent to get the price, please tell us in your email so that we will regard you inquiry priority.QWhat is your term of delivery?AWe accept EXW, FOB Shanghai or FOB Qingdao. You can choosethe one which is the most convenient or cost effective for you.QWhat about the lead time for the production?AHonestly, it depends on the order quantity and the season you place the order. In common 7~15 days.