Applicable Industries:Hotels, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Food Shop, Food & Beverage Shops

Showroom Location:Sri Lanka

Condition:New

Application:Food, Chemical, Pharmaceutical

Packaging Type:Capsule

Packaging Material:Plastic, Other

Automatic Grade:Automatic

Driven Type:Electric

Voltage:220V 50-60HZ

Place of Origin:HENAN

Brand Name:Runxiang

Dimension(L*W*H):2000*1050*1600

Weight:200KG

Warranty:1 Year

Key Selling Points:Automatic

Machinery Capacity:20000BPH, 1000BPH

Filling Material:Milk, Water, Oil, Juice, liquid

Filling Accuracy:±0.1%

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:2 years

Core Components:Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

Usage:Powder Products

Capacity:2000-30000bph

Function:capsule filling machine

Keywords:Fillng Machine

Material:304 stainless steel

Processing Types:Normal Pressure Filling

Advantage:Efficiency

Feature:High Precision Filling Level

Control:PLC+ Touch Screen

After Warranty Service:Video technical support, Online support, Spare parts

Local Service Location:Sri Lanka

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Certification:CE Certificate

Runxiang Semi Automatic Capsule Filling Machine for factory price

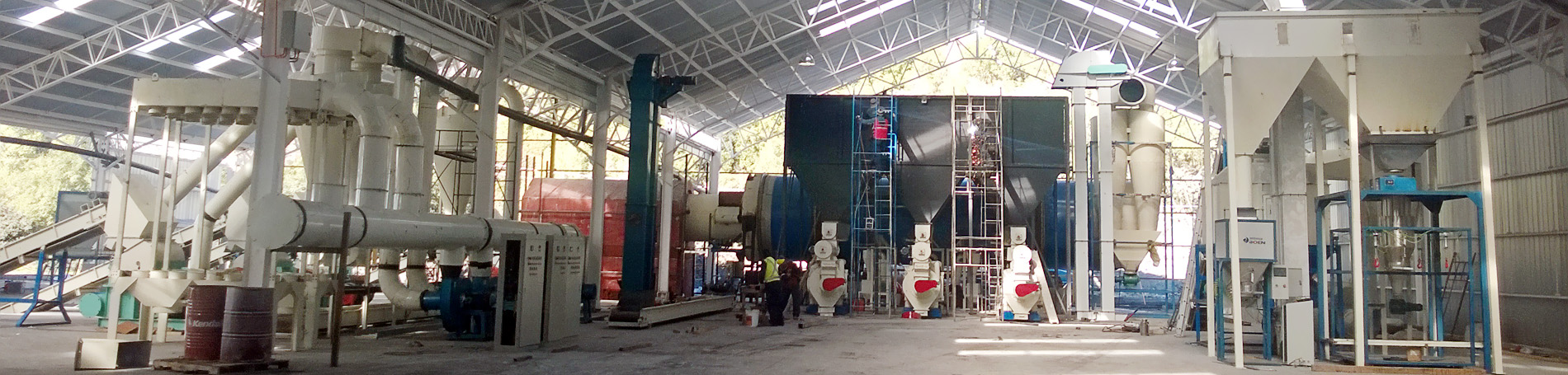

Our factory price vegetable oil production line is suitable for various oil-bearing seeds, including castor bean, mustard seed, cottonseed, sunflower seed, copra, hemp seed, corn germ, and more.

Raw material

Without shell nuts (sea coconut), maple seed kernel (traditional Chinese Medicine), seed kernel (traditional Chinese medicine),Cinnamomum camphora (traditional Chinese Medicine), castor bean (traditional Chinese Medicine), five seeds, safflower seed and so on.

Working priciple

Working priciple

Capacity: 35-50t/d (according to cottonseed)Prepress:100-150t/dResidual oil content in cake:10%-16%Motor powder: main engine 75KW, cooker 5.5KW, feeder 2.2KWNet weight:approx 8500KgDimension:3800*1240*3420mmCake thickness:8-20mmMotor current:120A-130AScrew spindle speed:32rpm or 38rpm

Advantage

Below features are based on oil plants above the average quality smoothly and continuously squeezed after such treatments as screening, husking, flaking and cooking, etc.Screw Soybean Seeds Oil Press / Groundnut Oil Mill Machine.Our machine adopt sea worthy wooden case packaging, safe and reliable.

Product Specification

Product Specification

| Model | 6YL-80 | 6YL-100 | 6YL-120 | 6YL-130 | 6YL-160 |

| Screw speed | 30-45r/min | 30-40 r/min | 30-40 r/min | 28-40 r/min | 28-40 r/min |

| Gear Ratio | 14/42×19/57=1:6.63 | 15/40×15/55=1:9.78 | 15/34×15/55=1:9.59 | 15/38×19/48=1:7.38 | 15/38×15/52=1:8.78 |

| Dimension | 1700*1300*1750mm | 2100*1360*1950mm | 2050x1350x2000mm | 2400x2300x1700mm | 2500x1600x2500mm |

| Productivity | 80-150kg/h | 150-250kg/h | 200-300kg/h | 250-400kg/h | 450-600kg/h |

| Power | 6-5.5KW | 6-7.5KW | 6-11KW | 6-15KW | 6-18.5KW |

| Vacuum pump | Y90S-4-0.55KW | Y90S-4-1.1KW | Y100L1-4-1.5KW | Y100L1-4-2.2KW | Y100L1-4-2.2KW |

| Heater | 2KW | 3KW | 3.3KW | 3.8KW | 4KW |

Company Profile

We are a large scale oil machinery manufacturer integrating research, development, design, manufacture and installation. Established in 1982, we have 210 senior engineering technicians among 580 staff, with investment amount of USD60,000.000, covering 10 hectares of factory area, 8 production workshops, 2 machining workshops,12 installation departments.We have 202 sets of automatic processing equipment, annual processing capacity is more than 3000 sets.Our oil machines sell well in more than 30 provinces, cities and districts, and exported to Kazakhstan, Tajikistan, Uzbekistan, Russia, Bolivia, Peru, Egypt, Bangladesh, Myanmar, Malaysia, Indonesia,Solomon Islands, Sudan, Rwanda and other countries and regions, and now we have developed into a major oil machinery manufacturing base in China.

Service

1.Quality warranty period is two years (except the wearing parts).Equipment must be 100% brand new when leaving factory. Malfunctions which are caused by machine-self and quality will be responsible for our manufacturer. 2. Whole lifetime maintenance free of charges. 3. Free training course at our plant. 4.Free technical support online or by phone communications&emails.5.Our engineer can be assigned to your country for testing and training as per your requirement.

FAQ

Usually the delivery time is 3-15 working days after prepayment received.Q7: What is the minimum quantity I must order?We don’t technically have minimums, but if you order more than 3 sets once,we can give you