Showroom Location:India, Colombia

Condition:New

Usage:Mustard Oil

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:97%-99%

Place of Origin:Henan, China

Brand Name:Lewin

Voltage:110V/220V

Dimension(L*W*H):77*34*46(cm)

Weight:31.5 KG

Warranty:1 Year

Key Selling Points:Energy saving

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Squeezer

Oil type:Flax Seed Oil, Soybean Oil, Rap seed oil, SESAME OIL, Pinenut oil, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, Palm Oil

Max Capacity:30 kg/h

Keyword:S10 new type screw sunflower seeds cooking oil pressers machine

Raw material:Soybean,sesame,olive,palm,peanut

Function:Making Edible Oil

Application:home use oil presser

Quality:Top Level

Advantage:Simple Operation,High oil yield

Selling point:Pure physical pressing, healthy nutrition

Character:Easy Movable

Price:Factory price

Machinery type:Automatic Micro Oil Mill Machine

S-10 new type screw sunflower seeds cooking oil pressers machine

Suitable type of Seed: soybean,almonds, sesame seeds, peanut, juglans,pine nuts,tea seeds , etc.

Raw material

Oil refining workshop application :Soybean oil, sunflower seed oil, Rapeseed Oil, cottonseed oil, peanut oil, palm oil, copra oil, rice bran oil all refined oil.

Working priciple

Working priciple

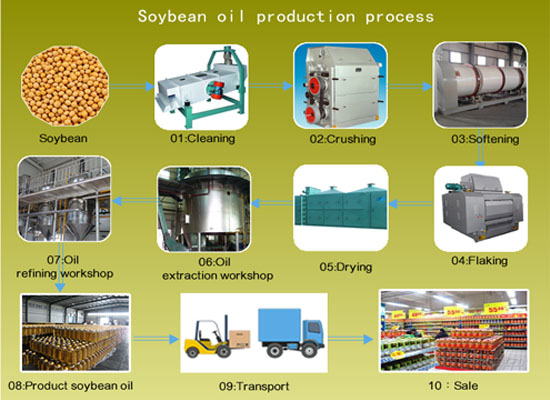

Main Process of cooking oil refinery machine:1. Degumming and deacidification: The gumming is moved by phosphoric acid and hot water. There are two ways to move the acid in the edible oil. One is chemical way, the other one is physical way. The chemical way is using NaOH to react with acid. This way is suitable for the capacity of 5-30T per day. The physical way is using steam and centrifugal to move the acid. This way is used for capacity from 30-2000T per day.2. Decolorization: This step is used to adjust the color of the oil. You can control the color of the edible oil according to the requirement of your market.3. Deodorization: The function of this step is to move the special smell in the oil. This is an important standard for refined edible oil.

Advantage

1. It is easy for people to learn, understand, and operate because of its small size. Besides, it is no special requirements for people to operate.2. It costs less various expenses with lower electricity consumption in use.3. The machine is a hydraulic machine with big pressure, high oil yielding rate and pure oil Quality.4. The machine adopts automatic control system, automatic preheating control and automatic pressure control of hydraulic system.

Product Specification

Product Specification

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

We are a professional manufacturer of oil covering an area of more than 20,000 square meters, with a standardized heavy industrial plant, is a collection of r & d production, sales as one of the powerful enterprises.

Service

Pre-sale services:1. Providing professional technical support.2. Send the product catalog and instruction manual.3. If you have any question PLS contact us online or send us email, we promise we will give you a reply at the first time!4. Personal call or visit are warmly welcome.Sale of services:1. We promise honest and fair, it’s our pleasure to serve you as your purchasing consultant.2. We guarantee punctuality, quality and quantities strictly implement the terms of contractAfter-sales service:1. Where to buy our products for 1 years warranty and life long maintenance.2. 24-hours telephone service.3. A large stock of components and parts, easily-worn parts.

FAQ

Q1: Why choose us? A: We are a factory, not just a trading company. It has its own independent research and development team and production workshop,inspection and quality control procedures to ensure that each purchased product meets global quality standards. Custom services are also available Q2: What about your warranty? A: Our warranty is 1 year. Q3: Is there anyinstallation direction after we received the machine? A: Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.