Applicable Industries:Hotels, Food & Beverage Factory, Restaurant, Home Use, Retail, Food Shop, Food & Beverage Shops

Showroom Location:None

Condition:New

Application:Food, Beverage, Commodity, Chemical, beer

Packaging Type:Cartons, CANS, Bottles, Barrel, Stand-up Pouch, Pouch, case

Packaging Material:Plastic, Metal, Wood

Automatic Grade:Automatic

Driven Type:Pneumatic

Voltage:Customized

Place of Origin:Jiangsu, China

Brand Name:Honor Machine

Dimension(L*W*H):customizable

Weight:2800 KG

Warranty:2 years

Key Selling Points:Long Service Life

Machinery Capacity:4000BPH, 8000BPH, 6000BPH, 400BPH, 500BPH, 2000BPH, 1000BPH

Filling Material:Beer, Water, Juice

Filling Accuracy:±0.1%

Marketing Type:New Product 2021

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:3 months

Core Components:Pump, Gear, Bearing

Product name:Oil Filling Machine

Capacity:1000-8000bph

Function:Filling Labeling Packing

Suitable bottle:PET/ Glass bottle

Bottle size:0.1-2L, 3-10L, 10-20L

Machine material:SUS304/316

Filling liquid:Oil / Chemcial / Sauce

Filling system:Piston Filling

Control system:PLC (SIEMENS)

After-sales Service Provided:2 years

Semi-automatic Small 500ml / 750ml / 1L bottle oil filling machine / Line

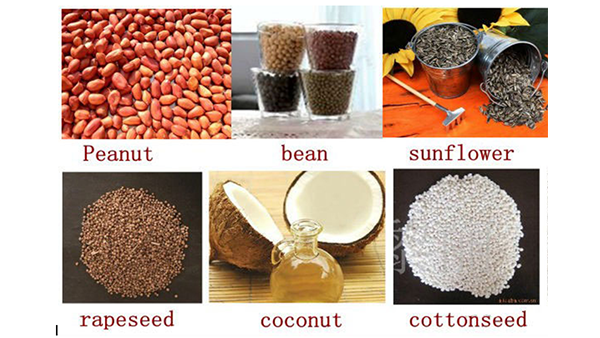

It can be used for oil extraction from peanut kernel, sunflower seed kernel,cotton seed, soybeans, rapeseed,safflower seed,castor seed and other oil crops.

Raw material

soybeans, perilla seed, shelled hemp, flax seed, flax seed,camellia seed, walnut, black sesame, rapeseed, sesame, sunflower seed.Sunflower seeds, almonds, red / white pepper seeds, peanut, pumpkin seeds, pine nut, coconut meat.

Working priciple

Working priciple

Oil solvent extraction section of vegetable oil production line:Cooking oil solvent extraction machine mainly include oil extraction system, desolventizing and toasting system, evaporation system and condensation system. Main theory is to use appropriate solvent extract oil from oilseeds embryo, then remove the solvent in mixed oil. Our oil extraction process technology to produce mixed oil without any chemical solvents, and can remove the tail gas directly, benefits environment protection.

Advantage

1.Large processing capacity2.Combined Steaming & Cooking3.Lower energy consumption4.Automatic and Continuous Operation5.Flexible production6.Higher quality oil and cake & Steady oil yield7.Perfect Construction, Simple Control and Durable service

Product Specification

Product Specification

| Type | 6YL-95DY | |||

| Capacity(t/24 h) | rapeseed | cottonseed | soybean | peanut kernels |

| 3.5-5 | 3.5-5 | 3.3-3.8 | 3.5-5 | |

| Oil Effiencicy(100%) | ≥95 | ≥95 | ≥95 | ≥95 |

| Equipped with power(kw) | Voltage:380V Power:11kw | |||

| Electric hearting part | Voltage:220V Power:2.8kw |

Company Profile

We are a reputed manufacturer and joint-stock enterprise with import & export rights andmainlyproduces oil press machinery and othersl equipment.Moreover, superior after-sales services guarantee highqualitycontinuously. In addition, we have a group of experienced and excellent after-sales service members who provide following up services for worldwide customers.Customers’ need is what we are trying to create. Customer satisfaction is what we are seeking. Over the last couple of decades, Benteng people have created continuously, transcending ourselves and insisting on the conceptof”Development is of overriding importance”. Develop the brand with quality. Promote the brand with service. We, Benteng people,areforging ahead for first-class brand with innovative spirit and do our best to contribute to the national industry.

Service

Pre-sales Service1.Offering comprehensive technical and business consultation services;2.Proposing th e most suitable scheme and equipment for our clients;3.Designing and fabricating targeted products according to the special requirements of clients;4.Training periodically high qualified service technician.After-sales Service1.Highly inspecting equipment in every working procedure, quality comes first;2.Fast & Safe Delivery;3.Assisting our clients for foundation construction of equipment;4.Dispatching engineers to install and debug equipment;5.Training the first-line operators on site;6.Regularly visit clients to solve production problems;7.Providing life-long maintenance service;8.Providing technical exchanging;

FAQ

1.Q:Can you guarantee the quality of your machine?A:We are a professional manufacturer with strict quality requirementsoil press machine2.Q:Does your factory accept customization?A:As a professional manufacturer, we can do almost any kind of customization.3.Q:What’s the delivery time?A:Generally after paying the final payment 3-5 days.4.Q:How long can I receive the goods after placing the order?A:7-15 days if there is no unexpected.5.Q:What should I do if the oil making machine will not be installed?A:Don’t worry, we have a perfect after-sales service system and can provide you video supports for free.6.Q:What’s your terms of payment?A:50% in advance, balance before shipment.