Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Retail, Other

Showroom Location:None

Condition:New

Application:Commodity, Chemical, Cosmetic

Packaging Type:Bottles, Other

Packaging Material:Plastic, Metal, Glass, Wood, Other, pltwood

Automatic Grade:Automatic

Driven Type:Electric

Voltage:220V/380V 3 phase

Place of Origin:Guangdong, China

Brand Name:LIENM

Dimension(L*W*H):L4200*W1200*H1830mm

Weight:560kgs

Warranty:1 Year

Key Selling Points:Flexible Manufacturing

Machinery Capacity:4000BPH, 6000BPH, 2000BPH, Other

Filling Material:Other, Water, Oil, Shampoo, Lotion, Cream

Filling Accuracy:±1%

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pressure vessel, Pump, PLC, Engine

Product name:Straight Line Following Filling Machine

Filling accuracy:±0.5%

Filling volume:50-1000ml,customized

Air pressure:0.4~0.6MPa

Control:PLC touch screen control

Suitable for:Shampoo,liquid,lotion,cream,gel,etc.

Material:Stainless steel 304 & 316

After-sales Service Provided:Engineers available to service machinery overseas, Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Market:Around the world

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:None

Certification:CE ISO9001

Servo Motor Automatic Mouthwash Filling Machine Hand Wash Filling Olive Oil Line Production Detergent Car Oil Filling Machine

Oil refining workshop application :Soybean oil, sunflower seed oil, Rapeseed Oil, cottonseed oil, peanut oil, palm oil, copra oil, rice bran oil all refined oil.

Raw material

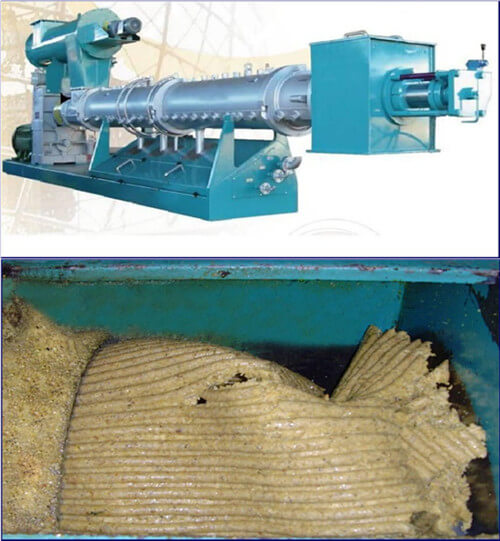

This cooking oil extraction machine is suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame seed, tea seed, walnut, corn germ, and so on.

Working priciple

Working priciple

Complete Edible Oil Manufacturing Unit includes♦ Cleaning process : Use vibration cleaning sieve and magnetic selector to get better cleaning effect.And This step is mainly to clean the big impurities ,like the stone, big dust , iron etc.♦ Crushing Process: This Process is mainly to crush the peanut , as the peanut is big ,it is not easy to press .We must crush the peanut to 6-8 pieces,then we need to peel .The rate of peel is about 90%.♦ Flaking Process : After crush and peel ,we need to flake the crushed sunflower , which make the cell wall of sunflower broken . And we flake the sunflower to 0.55 mm thickness .Then it is useful for the oil extracting..♦ Cooking Process: After the flaker,we need to cook the flaked sunflower , control the moisture at 5-7% ,the temperature is 110-115degree.♦ Oil-pressing : After all the pretreatment , pre- press the sunflower , the oil can be extracted about 76% .♦ Primary Oil Filtering Process: after the oil pressing, the crude oil will be primary filtered and for store to tank or for next process of oil refinery.

Advantage

Materials are all sanitary stainless steel 304 or 316L .Humanized structure design and easy to operate .Transition area of interior wall on tank adopts arc for transition to ensure no dead comer of sanitation .

Product Specification

Product Specification

| Item | 5TPD Peanut oil production line |

| Capacity | 5TPD |

| Power | 44kw |

| Installation size | Oil pressing line+oil refining line+oil filling line15m*2.5m*4.5m(L*W*H) |

Company Profile

Our company is a large-scale modern manufacturing company specialized in the R&D, manufacturing and sales of food oil processing machinery, which covers an area of 18,000 square meters. Numerous plants are installed in Netherlands, Kazakhstan, Malaysia, Nigeria, Nepal, Bangladesh, Sri Lanka, Indonesia, Bulgaria, New Zealand, Peru, South Africa, and Saudi Arabia, etc..We have our own showroom to showcase our products.You can meet all products there.Welcome to Company.

Service

1, 1 year free warranty. Whole lifetime maintenance.2, Supplying wearing parts all year around.3, Supporting technical solutions at any time.4, Helping design and plan the oil plant’s construction.5, Providing installation video.6, Tried orders are available.7, Developing agents with good policies around worldwide.Service before sale1.One-on-one exclusive customer service staff, 24 hours online.2.Inquiry, email, message will be replied at first time.3.Supply professional technical parameters, video picture sharing, project design.Service on sale1.Ensure customer payment security.2.Ensure the customer’s price is stable and reasonable.3.Insist on quality first the production standard, every machine before leave the factory we test it ensure the quality is good. Service after sale1.Arrange high-efficiency delivery and safe transport.2.Supply installation training, direction for use, maintenance instructions, techinical support, all necessary documents you need and oversea service.

FAQ

1. Q: Are you a trading company or a manufacturer ? A: We are a manufacturer, which has long experience in this industry. 2. Q: How can I get to your company ? A: You can get a flight to Xinzheng Airport. We are just about 40- 50mins away from Xinzheng Airport. 3. Q: How long is your guarantee ? A: One year(Calculated from the equipment arrives the customer’s side.). After this period we will definitely support you when needed. You will be welcome to contact us with any problem may happened. 4. Q: Will you send engineers to install the plant?A: yes, but at an extra cost payable by the customer. Or you can get local contractors to do the commissioning and we send one supervising engineer.5. Q: Do you have some foreign customers using your equipment?A: yes, we have our company has established business relationships with customers in Russia, German, Slovakia, Ukraine, Vietnam, Pakistan, the Philippines, Indonesia, Thailand, Pakistan, Egypt ,Iraq, Jordan, Saudi Arabia, Syria, Libya etc.