Showroom Location:Peru, South Africa, Nigeria, Malaysia

Condition:New

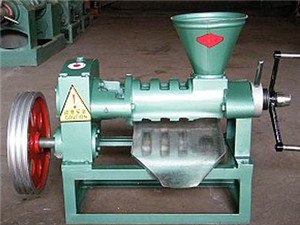

Usage:Soyabean Oil Press line

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:98%

Place of Origin:Henan, China

Brand Name:Qie

Voltage:220V/380V/440V

Weight:20000 KG

Warranty:1 Year

Key Selling Points:High Productivity

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor

Oil type:Soybean Oil, SESAME OIL, sunflower seed oil, Peanut Oil

Max Capacity:1000tpd

Product name:Peanut Groundnut Oil Production Line For Small Businesses

Raw material:oil seeds

Keyword 1:soya bean line oil

Keyword 2:cocking oil production line

Keyword 3:cooking oil production line machine

Factory visit:welcome

Soya Bean Oil Processing Line Cocking Oil Production Line Machine

rapeseed, cottonseed, soybean, peanut, flaxseed, palm, coconut shell, olive fruit, castor bean, sesame, sunflower, rice bran, corn germ, walnut, almond, evening primrose, Pine seeds, animal skin, clay and all oil crops.

Raw material

Plant raw materials: Rice bran, soybean, peanut, rapeseed, cottonseed, sunflower, palm, teaseed, flaxseed, corn germ, sesame, flaxseed, walnut, peony seed, castor bean, safflower seed, wheat germ…

Working priciple

Working priciple

Brief processes:Fresh Solvent–Cake–Extracting–Wet Meal–Desolventising–Meal–Miscella–Evaporating and stripping–Solvent mixture–Condensing and Recovering–Crude Oil–Solvent Recycling–Refining Workshop.

Advantage

1) Simple structure ,easy in installation and maintation. 2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts. 3) Running in a high automatization and intellectualization,no pollution 4) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine . 5) Suitable to losts raw materials such as peanut, sunflower seeds, black seeds, olive, coconut, flax seeds, etc.

Product Specification

Product Specification

| Model | 6YL-80 | 6YL-100 | 6YL-120 | 6YL-130 | 6YL-160 |

| Screw speed | 30-45r/min | 30-40 r/min | 30-40 r/min | 28-40 r/min | 28-40 r/min |

| Gear Ratio | 14/42×19/57=1:6.63 | 15/40×15/55=1:9.78 | 15/34×15/55=1:9.59 | 15/38×19/48=1:7.38 | 15/38×15/52=1:8.78 |

| Dimension | 1700*1300*1750mm | 2100*1360*1950mm | 2050x1350x2000mm | 2400x2300x1700mm | 2500x1600x2500mm |

| Productivity | 80-150kg/h | 150-250kg/h | 200-300kg/h | 250-400kg/h | 450-600kg/h |

| Power | 6-5.5KW | 6-7.5KW | 6-11KW | 6-15KW | 6-18.5KW |

| Vacuum pump | Y90S-4-0.55KW | Y90S-4-1.1KW | Y100L1-4-1.5KW | Y100L1-4-2.2KW | Y100L1-4-2.2KW |

| Heater | 2KW | 3KW | 3.3KW | 3.8KW | 4KW |

Company Profile

We are a Professional and modern grain and oil machinery engineering equipment manufacturer integrating research, manufacturing and installation. We have obtained rich experience and practice in palm fruit oil machine, vegetable oil pretreatment, prepress,extraction, sophisticated technology and equipment designs etc, owing wide international market in more than 130 countries and regions.With more than 30 years of experience on oil making machine, we provide a comprehensive range of products We are proud to guarantee that, with our strong technical background and communication capability, our sales/support engineers are able to answer your most complicated technical questions over the phone in English. That would save a lot of time for communication.The following pictures show our company and customers in our workshop.

Service

Our company always put the interests and quality of its clients first, insists the principle that there is no best but only better service. We will commit to provide quality products and improve on-site service and service after selling. Specific commitments are now as follows:We will organize an experienced engineering team, managed by the Project Manager.Ensure high-quality materials, excellent service provided to the user;During the installation process, we will appoint a technical and installation supervision services at the scene.We do debugging of stand-alone equipment and on-line debugging and commissioning test run to ensure normal operation of the project at full load conditions.Supply the technical of your staff to ensure training of personnel to operate independently for free.To ensure that once installation acceptance; Within one month, to provide customers with qualified acceptance after completion of archive.To ensure timely provision of equipment and accessories;We have developed new products, new technology, will give priority to customers;In the equipment’s warranty period (within 12 months of the date of commissioning qualified):Due to the quality of the equipment itself damage, we will repair or replace parts.Damage due to customer reasons, only charge the material cost for repair or replacement by the buyer. After the customer informed our company, we will put forward a propose within 24 hours, using the fastest way to resolve the issue the required components.We are willing to supply good service on your business development.

FAQ

Chrome steel or Stainless steelQ6: How long does it take to produce the machine once I place my order ?