Usage:SUNFLOWER OIL

Type:oil refinery machine

Automatic Grade:Automatic

Production Capacity:98%-100%

Place of Origin:Henan, China

Brand Name:HENGYI

Voltage:220V/380V

Dimension(L*W*H):3750*850*1990MM

Weight:880kg

Warranty:1 Year, 12 Months

After-sales Service Provided:Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

Certification:CE ISO

Name:palm oil fractionation machine

Raw material:Soybean, sesame, sunflower, peanut;

Model:JL-500

Capacity:3 ton

Function:Chemical Oil Refining

Material:Stainless Steel SS304/316

No.of refinery tank:4

Heating power:37.45kw

Advantage:High Oil Yield

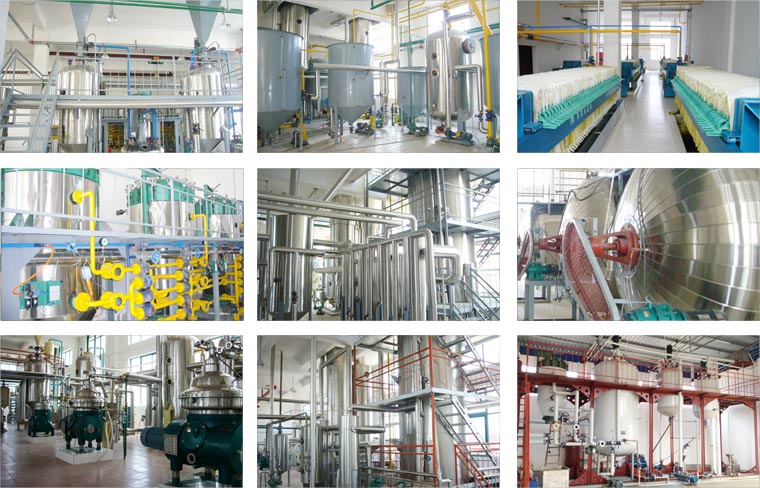

Soybean Oil Refining plant in Korea/Oil winterisation equipment/palm oil fractionation machine

Suitable for sunflower seeds, rapeseed, oleander, soybean, tea seed, pepper seed, sesame, peanut.

Raw material

Our screw small coconut oil press machine can process a great many plant seeds, such as peanut, soybean, sunflower seeds, sesame seed, cottonseed, rapeseeds, corn germ, coconut, palm kernel, jatropha seed, hemp seed, castor seed, etc.

Working priciple

Working priciple

Generally, sunflower oil production line does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extracting crude oil from these seeds, and then further refining the oil obtained before packaging.Cleaning the SeedsThe harvested oil-bearing seeds are passed over magnets to remove any metal traces, and other impurities are being got rid of by cleaning sieve and destoners. Then the outer covering (hulls) of the seeds are removed to obtain pure seeds.Grinding the SeedsThe de-hulled seeds are ground into coarse meal to provide a larger surface area to be pressed. Hammer mills or grooved rollers are used to crush the coarse meal into uniform fine particles. Then the meal is heated to enable oil extraction, though impurities are released with oil during this process and such impurities should be removed before the oil is declared edible.PressingThe heated meal is fed into a screw oil press which progressively, at the same time, the oil is squeezed out through the slots in the barrel and recovered.Refining of the OilOil refining involves removal of the bitterness, color, and odor. First, the oil is heated at temperatures between 40 0C and 85 0C. Then it’s mixed with an alkaline substance like sodium carbonate or sodium hydroxide. The oils are degummed by treating them with heated water at temperatures between 85 0C and 95 0C or with acidified water. This precipitates out most of the gums usually phosphatides. Then centrifugation is done to remove the dregs.

Advantage

1, to reduce wear and tear on the follow-up equipment, improve environmental quality workshop;2, improve equipment production, improve oil yield, to ensure maximum quality fat, meal and byproducts;3, the lowest rate of fuel crushing, destructive for protein meals minimum.

Product Specification

Product Specification

| Model | ZY-80 | ZY-100 | ZY-125 | ZY-150 | |

| Power | Power | 5.5kw | 7.5kw | 15kw | 22kw |

| Pump | 1.1kw | 1.1kw | 1.5kw | 2.5kw | |

|

Heater |

2KW | 2.2kw | 2.8kw | 4.5kw | |

| Capacity | 80-130kg/h | 140-280kg/h | 350-400kg/h | 350-450kg/h | |

| Weight | 780kg | 1100kg | 1500kg | 1500kg | |

| Dimension(mm) | 1700*1200*1500 | 1800*1300*1680 | 2100*1400*1700 | 2500*1750*2000 |

Company Profile

We are a manufacturer of edible oil making machine, and founded in 1976 with well-equipped testing facilities and strong technical force. With good quality, reasonable prices and stylish designs, our products are extensively used in edible oil production and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Service

Ensure the quality100% test before delivery All products undergo strict product quality testing before packing.Customized serviceWe are an industry and trade integrated company, has its own production workshop has its own research team. Provide personalizedcustomization service.Rich experienceMore than 30 years independent research and development, independent production experience. Excellent customer service andtechnical support.

FAQ

1.Q: What’s the payment terms?A: T/T,Trade Assurance,Western Union, MoneyGram,L/C, Cash etc.2.Q: What kind of seeds that the machine can press?A:The cold press oil machine can press the peanuts,sunflower,ricino,coconut, almond, canola seed,walnut, copra,palm kernels, rapeseed, flaxseed,coconut, cotton seeds, sesame,soybeans,flax seed,etc.