Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Farms, Retail

Showroom Location:Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Japan, Malaysia, Australia

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2020

Warranty of core components:1 Year

Core Components:Bearing, Motor

Model Number:LZ-0.5, LZ-1.5, LZ-2.5

Brand Name:hanlong

Place of Origin:Jiangsu, China

Voltage:220v-440v

Power:1.1-15

Dimension(L*W*H):2020*640*1560mm

Weight:300 KG

Warranty:1 Year

Application fields:Snack food factory, Dairy products factory, Fruit processing plant, Cooking oil factory, Winery, Vegetable processing plant, Cannery, Beverage Factory, Seasoning plant, Frozen food Factory

Raw material:Fruit, Vegetables, Wheat

Key Selling Points:High Productivity

Application:Fruit Vegetable

Function:Juicer Extracting

Keywords:Orange Juicer Extractor Machine

MOQ:1PC

Capacity:1.5T

Material:SUS304 Stainless Steel

Type:Automatic Juicer

Final product:Industrial Cold Press Juicer Machine

Usage:Commercial Usage

Product type:Crushing

Squeezer Price Fruit Juice Processing Plant Tomato Sauce Sprial Juicing Screw Juicer Machine

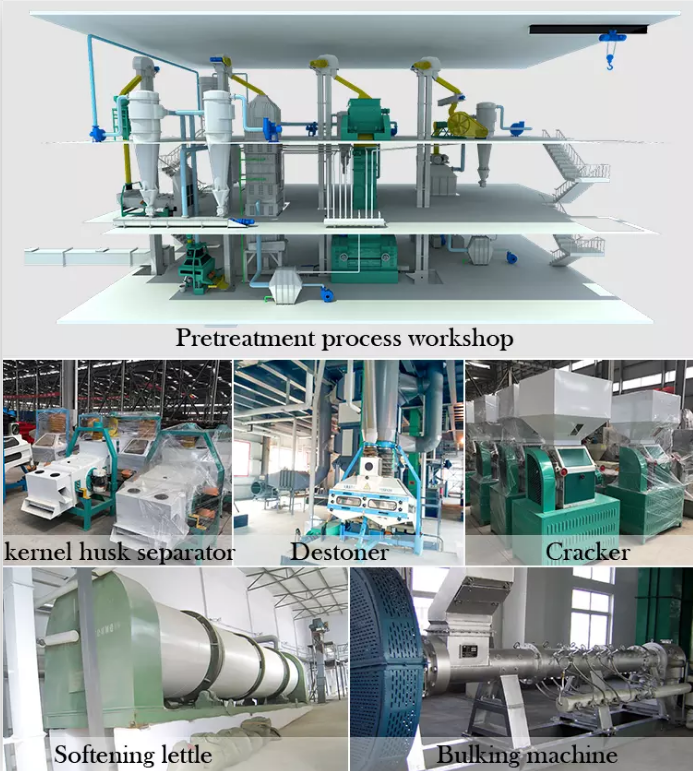

1.Hot oil material classes: sesame seeds, flax, peanut, wheat germ, corn germ, etc;2.Cold oil material classes: pine seeds, almonds, olive, walnuts, camellia seed, macadamia nuts, etc3.Spices and traditional Chinese medicine,pepper, mustard seed, purple perilla, etc;4.Good quality oil,pure physical squeeze, high oil, does not destroy the organic components of oil.

Raw material

Raw amterials: Such as copra, cottonseeds, soybean, rapeseeds, peanut, sunflower seeds, tea seeds, olive,etc.

Working priciple

Working priciple

depending on the oil, the production process different crude oil, customer demand for products of different, the size of the processing and refining method is different, our company’s refining equipment is divided into three types: batch refining equipment and semi continuous refining equipment and continuous refining equipment.

Advantage

When the oil press is running, the processed material embryo enters the squeezing chamber from the hopper. The helix of the squeezed screw is pushed in and squeezed. The material embryo is carried out in the pressing chamber of the oil press. Under the condition of high pressure, there is a great friction resistance between the material embryo and the squeezing and squeezing chamber. The heat caused by the heat caused the thermal denaturation of the protein in the embryo, destroyed the colloid, increased the plasticity, and also reduced the viscosity of the oil and thus precipitated oil easily. The oil production rate of the oil press is improved.

Product Specification

Product Specification

| Project name | capacity | suitable for raw material |

| oil pressing production line | 10–800t/d | sunflower seed, soybean, peanut, sesame, corn germ, tea seed, rapeseed, cottonseed, etc |

| oil solvent-extracting production line | 30–800t/d | pressed oil cake, soybean flakes, rice bran pallet, etc. |

| oil refining production line | 3–500t/d | all kinds of vegetable oil |

| palm oil mill production line | 5t/h–90t/h | palm fruit bunch |

| oil fractionation production line | 20–500t/d | refined palm oil |

| Oilseeds protein, phospholipids | 50–500t/d | soybean meal, etc. |

| grain deep processing line | 20–1000t/d | corn, wheat, beans, etc. |

Company Profile

The company has long been engaged in the research, design, manufacturing of mechanical products.The company is a national standard drafting unit of agricultural screw oil press and a national high-tech enterprise. It has passed the ISO9001 quality management system certification of China Quality Certification Center. The products are sold at home and broad.In recent years, in order to make edible vegetable oil more environmentally friendly and safer, the company has accelerated its product improvement design work, prompting the conversion of oil presses from agricultural and sideline products processing machinery to food processing machinery.

Service

Pre-sale services:1. Providing professional technical support.2. Send the product catalog and instruction manual.3. If you have any question PLS contact us online or send us email, we promise we will give you a reply at the first time!4. Personal call or visit are warmly welcome.Sale of services:1. We promise honest and fair, it’s our pleasure to serve you as your purchasing consultant.2. We guarantee punctuality, quality and quantities strictly implement the terms of contractAfter-sales service:1. Where to buy our products for 1 years warranty and life long maintenance.2. 24-hours telephone service.3. A large stock of components and parts, easily-worn parts.

FAQ

A : Manufactured strictly based on national and international standard, and we take a test on every equipment before delivery.5.Q:Can you install the machine in local place?A: Yes, engineers can be dispatched to your local place for installation and commissioning, also provide operation training.6.Q: What’s the payment terms?A:T/T,Trade Assurance,Western Union, MoneyGram,L/C, Cash etc.