Showroom Location:None

Condition:New

Usage:Peanut Oil

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Place of Origin:Henan, China

Brand Name:YunShan

Warranty:1 Year

Key Selling Points:High-accuracy

Marketing Type:Hot Product 2019

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Engine

Name:hydraulic oil press machine

Raw material:Oil Seeds/Peanut Oil/Palm oil

Material:Carbon Steel Stainless Steel

Function:Oil Press + Drum Filter

MOQ:1set

port:qingdao/shanghai

Packaging:container

Weight:Based on capacity

Color:according to customer’s requirement

After Warranty Service:Video technical support, Online support

Local Service Location:None

After-sales Service Provided:Video technical support, Online support,attrValueId:190000884

Stainless steel household cold press oil machine commercial oil press wholesale

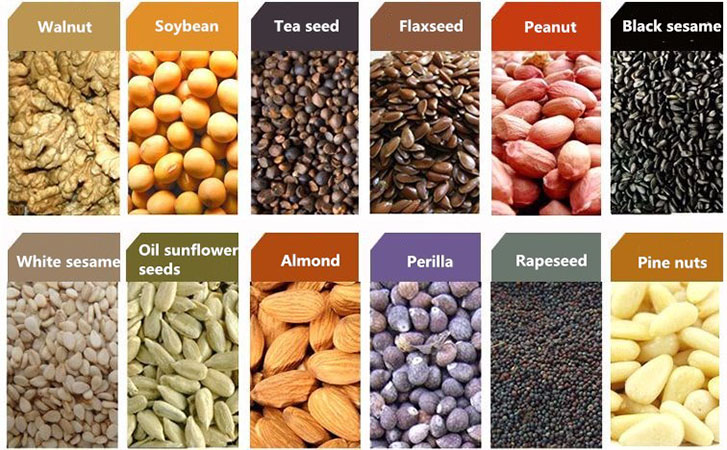

Plant raw materials: Rice bran, soybean, peanut, rapeseed, cottonseed, sunflower, palm, teaseed, flaxseed, corn germ, sesame, flaxseed, walnut, peony seed, castor bean, safflower seed, wheat germ…

Raw material

suitable to all kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Working priciple

Working priciple

Main Equipments of edible oil extraction machine:1. Solvent pumps: continuously spray solvent to the rotary-typr extractor.2. Roary extractor: spray and soak the cake with solvent so that oil fats can be dissolved in solvent (form miscella). After processing, you can get wet meal and miscella (mixed oil).3. DTDC: used to separate the solvent from the wet meal.4. Miscella tank 1st: pump the miscella ( oil with solvent) into the miscella 1st, then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.5. Miscella tank 2nd: the purified miscella will be pumped into it.6. Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.7. Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

Advantage

1.304/316 SUS 2.Customized crude oil refining line capacity. We customize plant as per your requirement for the capacity.3. Flexible usage. The crude oil refining line can work independently or together with whole oil production line.4. Two sets centrifugal machine make sure all continuous production , degumming result is very good.5.The refined oil has high quality and is good for long time storage.6. Oil can reach national standard(LEVEL 2), it can be sold in supermarket.

Product Specification

Product Specification

| Model | 6YL-60 | 6YL-80 | 6YL-100 | 6YL-120 | 6YL-160 | |

| Dia. | Φ53mm | Φ81mm | φ101mm | φ123mm | φ160mm | |

| Screw speed | 64 r/min | 47r/min | 38r/min | 35r/min | 32r/min | |

| Power | Motor | 1.5-2.2kw | 5.5kw | 7.5kw | 11kw | 22kw |

| Vacuum pump | 0.18kw(VP-1.5) | 0.55kw | 0.75kw | 1.1kw | 1.1kw | |

| Heater | 0.9kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw | |

| Capacity | 4.-60kg/h | 80-100kg/h | 150-200kg/h | 250-300kg/h | 500-600kg/h | |

| Weight | 268kg | 880kg | 1250kg | 1500kg | 1800kg | |

| Size(mm) | 1020*720*798 | 1500*1200*1750 | 2000*1300*1850 | 2100*1300*1850 | 2300*1300*1950 |

Company Profile

We offer many different products to cater to different markets all-over the world and to offer a more customized experience and services to individual customers.we own a complete production line for brick machines only as well as block machines. By having great business relationships with location companies, we have ensured a steady supply of materials,which makes short wait times and excellent customer purchasing experience. This makes customers a worry free, “one-stop”shopping location for our customers.

Service

Pre-sales Service1.Offering comprehensive technical and business consultation services;2.Proposing th e most suitable scheme and equipment for our clients;3.Designing and fabricating targeted products according to the special requirements of clients;4.Training periodically high qualified service technician.After-sales Service1.Highly inspecting equipment in every working procedure, quality comes first;2.Fast & Safe Delivery;3.Assisting our clients for foundation construction of equipment;4.Dispatching engineers to install and debug equipment;5.Training the first-line operators on site;6.Regularly visit clients to solve production problems;7.Providing life-long maintenance service;8.Providing technical exchanging;

FAQ

1.Q: Which kind of oil materials can be processed?A: All kinds of oil seeds. For example of common oil material:soybean, rice bran, corn germ, cottonseeds, peanut, sunflower, rapeseed, palm fruit etc.2. Q: What’s the input capacity of your machinery?A: 5-2000 tons per day. the input capacity is according your plan or requirements to customized.3. Q: The materials of your machinery?A: The stainless steel and carbon steel.4.Q: How should I do if meet some trouble while using?A:we can supply English manual book and also take a video for showing how to resolve the problems or dispatch our worker to your factory.5. Q: Can you install the machine in local place?A: We will send our engineers to local place to help installing the machine and provide technical guidance.6.Q: The production method of your oil machinery?A:divided into cold press and hot press two kind according the temperature,have physical direct press and solvent extraction etc. our machine can be meet your oil production.if any quotation,contact me free.7.Q: How long can we receive the goods?A:delivery about 45 working day after your order,have different shipping time of different machinery,and we will inform you shipping time based on your seaport.