Applicable Industries:Manufacturing Plant, Food & Beverage Factory

Showroom Location:None

Condition:New

Application:Food, edible oil

Packaging Type:Bottles, Barrel

Packaging Material:Plastic, Metal, Glass

Automatic Grade:Automatic

Driven Type:Electric

Voltage:3 phase 380V

Place of Origin:Guangdong, China

Brand Name:TGM

Dimension(L*W*H):1500x1100x1950mm

Weight:260 KG

Warranty:1 Year

Key Selling Points:High-accuracy

Machinery Capacity:4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH, 3000BPH

Filling Material:Oil, edible oil

Filling Accuracy:3-5ml

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:2 years

Core Components:Pump, PLC, Gear, Bearing

Product name:thick oil filling machine

Function:liquid oil automatic filling

Bottle type:any shape

Bottle material:iron, plastic, glass etc.

Filling range:100ml-5000ml,5000ml-25000ml

Filling speed:600 – 3000BPH

Material:SUS304/316

Keywords:Filling Machine

Filling type:flow meter type filling machine

Filling head:2heads/4heads/6heads/8heads/10heads/12heads

TANG Full automatic soybean oil filling machine oil canning production line liquid filling equipment manufacturers direct sales

The machine Could press rapeseed, cottonseed, soybean, peanut, flaxseed, palm, coconut shell, olive fruit, castor bean, sesame, sunflower, rice bran, corn germ, walnut, almond, evening primrose, Pine seeds, animal skin, clay and all oil crops.

Raw material

Small business flaxseed sesame oil press groundnut processing oil machine is suitable with most raw materials, such as sesame, soybean, coconut, peanut, palm kernel, coffee bean, sunflower seeds, sea buckthorn seeds, moringa seeds, etc.

Working priciple

Working priciple

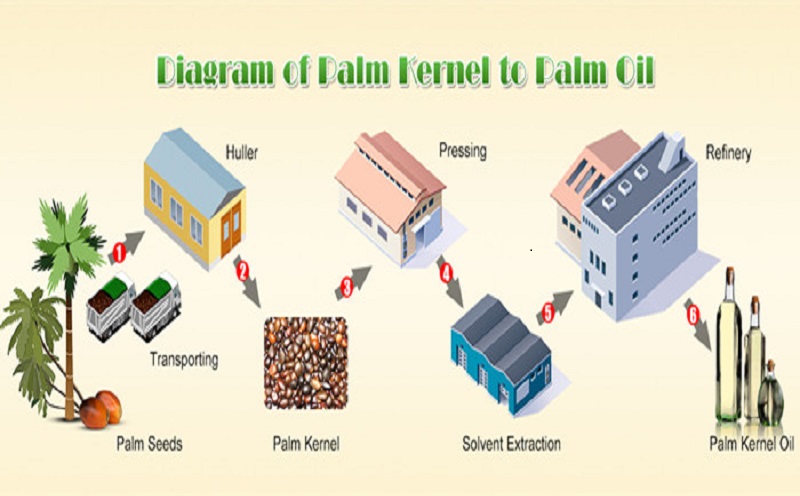

Generally, sunflower oil production line does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extracting crude oil from these seeds, and then further refining the oil obtained before packaging.Cleaning the SeedsThe harvested oil-bearing seeds are passed over magnets to remove any metal traces, and other impurities are being got rid of by cleaning sieve and destoners. Then the outer covering (hulls) of the seeds are removed to obtain pure seeds.Grinding the SeedsThe de-hulled seeds are ground into coarse meal to provide a larger surface area to be pressed. Hammer mills or grooved rollers are used to crush the coarse meal into uniform fine particles. Then the meal is heated to enable oil extraction, though impurities are released with oil during this process and such impurities should be removed before the oil is declared edible.PressingThe heated meal is fed into a screw oil press which progressively, at the same time, the oil is squeezed out through the slots in the barrel and recovered.Refining of the OilOil refining involves removal of the bitterness, color, and odor. First, the oil is heated at temperatures between 40 0C and 85 0C. Then it’s mixed with an alkaline substance like sodium carbonate or sodium hydroxide. The oils are degummed by treating them with heated water at temperatures between 85 0C and 95 0C or with acidified water. This precipitates out most of the gums usually phosphatides. Then centrifugation is done to remove the dregs.

Advantage

Pre-Sales Service* Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas.

Product Specification

Product Specification

| Model | ZY-80 | ZY-100 | ZY-125 | ZY-150 | |

| Power | Power | 5.5kw | 7.5kw | 15kw | 22kw |

| Pump | 1.1kw | 1.1kw | 1.5kw | 2.5kw | |

|

Heater |

2KW | 2.2kw | 2.8kw | 4.5kw | |

| Capacity | 80-130kg/h | 140-280kg/h | 350-400kg/h | 350-450kg/h | |

| Weight | 780kg | 1100kg | 1500kg | 1500kg | |

| Dimension(mm) | 1700*1200*1500 | 1800*1300*1680 | 2100*1400*1700 | 2500*1750*2000 |

Company Profile

We are engaged in food grain and oil engineering design, new technology development, machinery and equipment manufacturing, engineering, installation and commissioning of the entire training services in one of the professional engineering company.Company institutions are: engineering technology, marketing services, integrated management of the Ministry of Finance Management Department, machinery manufacturing center and research and development centers and other departments. Including engineering and technical design staff of nearly 20 people, designed to work in all computer operations, forming a set of scientific research, production and development as one of scientific research and development based engineering company.In recent years, the company has completed hundreds of projects involving oil pre-pressing, extraction, oil refining, animal oil refinery processing, small species of oil refining and biodiesel, a project covering more than 20 domestic provinces, municipalities and autonomous regions, and exports of South Africa, Ethiopia, South Asia, Pakistan, Russia and dozens of countries, the company manufacturing may bear 2000t / d pre-crushing and leaching, 600t / d refinery, 100t / d of biodiesel and other large equipment and engineering installation and commissioning.Companies adhere to the “credibility of the first, leading technology” business philosophy, and gradually formed a service-oriented corporate culture. Adhere to high standards, to provide customers with high quality personalized service.

Service

Pre-sales service1.Quick response2.Detailed quotation3.Professional production and transportation solutionAfter-sales service1.Warranty policy one year from shipment2. We will send you the replacement after received the broken part3. Evaluate the customs risk and choose safest shipping company before shipping.4. Follow status up time by time until the goods arrived.

FAQ

Q1:WHY BUY FROM US?1) As a real manufacturer, we can supply the best quality machines with reasonable price.2) All the machines pictures and features are real, captured by us, NO Cheating, NO Fraud.3) We are able to get the exactly products for you since we know these machines very well4) We can supply the parts and service in long future.Q2: ARE YOU A NEW MANUFACTURER?A2:We are a major oil press manufacture with a long history in China, in the past decades, we’re focused on domestic market and exporters. Q3: DO YOU HAVE OTHER PRODUCTS ?A3: Yes, we do have a lot of products over than this sit, please feel free to ask us any questions about our products.