Applicable Industries:Food & Beverage Factory, Food Shop, Food & Beverage Shops

Showroom Location:None

Condition:New

Application:Food, Beverage, Etc. Industry

Packaging Type:CANS, Bottles, Bags

Packaging Material:Plastic, Metal, Glass

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380V

Place of Origin:Shanghai, China

Brand Name:Leadworld

Dimension(L*W*H):OEM

Weight:1500 KG

Warranty:1 Year

Key Selling Points:Easy to Operate

Machinery Capacity:4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

Filling Material:Beer, Milk, Water, Oil, Juice, Powder, Tomato Paste

Filling Accuracy:±0.5%

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pressure vessel, PLC, Gear, Bearing, Gearbox, Engine

Product name:Tomato Paste Filling Production Line

Function:Filling Sealing Forming

After-sales Service Provided:Online Support, Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Name:Bottle Liquid Filling Machine

Usage:Filling Capping Labeling Packaging

Bottle type:PET Plastic Bottle

Keywords:Fillng Machine

Processing Types:Automatic Bottle Filling Sealing Machine

Suitable for:Paste Liquid Cream

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:None

Certification:CE

Tomato Paste Production Line Making Machine Tomato Paste Process Line

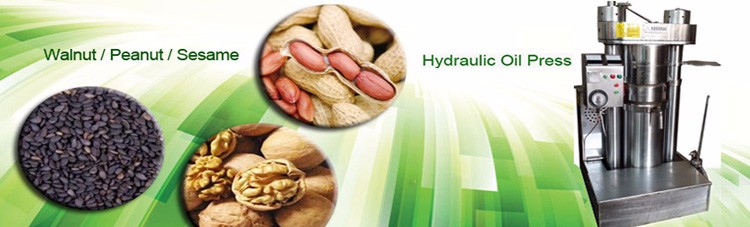

This screw cold&hot press series can process sesame seed, rapeseed, peanut, soybean, cottonseed, almond, Tung-oil seed, sunflower seed, tea seed, walnut, caster seed, Perillaseed , Hazelnut,oil palm, oil olive, avocado, pomegranate seed , pistachio nut, neem seed, coconut, totally about 150 types of seeds , nuts,beans , fruits and oil crops;

Raw material

Edible oil press machine, which is also called oil expeller, oil extraction machine or oil mill, It can be used for various raw materials, such as soybeans, peanuts, cotton seeds, rape seeds, sesame seeds, sunflower seeds, canola seeds, coconut seeds, tea seeds, palm seeds and jatropha seeds.

Working priciple

Working priciple

Working principle of il refining machine:Detailed process of our small edible oil refinery machine:Crude oil-→deguming and deacidification-→decoloring-→fine filtering-→final product oil-→process finished

Advantage

When the oil press is running, the processed material embryo enters the squeezing chamber from the hopper. The helix of the squeezed screw is pushed in and squeezed. The material embryo is carried out in the pressing chamber of the oil press. Under the condition of high pressure, there is a great friction resistance between the material embryo and the squeezing and squeezing chamber. The heat caused by the heat caused the thermal denaturation of the protein in the embryo, destroyed the colloid, increased the plasticity, and also reduced the viscosity of the oil and thus precipitated oil easily. The oil production rate of the oil press is improved.

Product Specification

Product Specification

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

We are a Professional and modern grain and oil machinery engineering equipment manufacturer integrating research, manufacturing and installation. We have obtained rich experience and practice in palm fruit oil machine, vegetable oil pretreatment, prepress,extraction, sophisticated technology and equipment designs etc, owing wide international market in more than 130 countries and regions.With more than 30 years of experience on oil making machine, we provide a comprehensive range of products We are proud to guarantee that, with our strong technical background and communication capability, our sales/support engineers are able to answer your most complicated technical questions over the phone in English. That would save a lot of time for communication.The following pictures show our company and customers in our workshop.

Service

1. One year quality warranty for the machine and spare parts2. Overseas engineers service for installation3. Whole-life after-sales service and free consultation4. Customized requirements available5. Technician guide at the site.6. 24Hr online service

FAQ

1.Q :Are you the factory? A:Yes, We are a professional manufacturer for more than 10 years.2.Q: Where is your factory located? A:Our factory is located in Zhengzhou, Henan Province.3.Q:How about the INSTALLATION? A:Engineers are available to service machinery overseas,including installation,commission and training,etc. 4.Q:Can your company accept the customized product? A:Yes,OEM &ODM service is available.We can make the products according to your size,design,color, It will be better if you can send us the product pictures for our reference.5.Q: How does your factory do regarding quality control? A: Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.Any questions, please don’t hesitate to contact us!