Showroom Location:None

Condition:New

Usage:Peanut Oil

Type:Cold & Hot Pressing Machine

Automatic Grade:Semi-automatic

Production Capacity:13kgs/h

Place of Origin:Guangdong, China

Brand Name:YTK

Voltage:220V

Dimension(L*W*H):650*505*980mm

Weight:60 KG

Warranty:1 Year

Key Selling Points:Easy to Operate

Marketing Type:New Product 2022

Machinery Test Report:Not Available

Video outgoing-inspection:Not Available

Warranty of core components:1 Year

Core Components:Motor

Oil type:SESAME OIL, sunflower seed oil, Coconut Oil, OLIVE OIL

Max Capacity:13KGS/H

Product name:13KGS/H Capacity Home Use Vegetable Seeds Oil Pressers Machine

key words1:sesame oil extraction machine for home

key words2:oil making machine

key words3:oil press machine home

key words4:oil pressers

key words5:oil presser

key words6:oil machine

key words7:olive oil machine

key words8:Oil Extraction Machine

key words9:commercial mini oil press machine

YTK-P20 High Quality 13KGS/H Capacity Home Use Vegetable Seeds Oil Pressers Machine

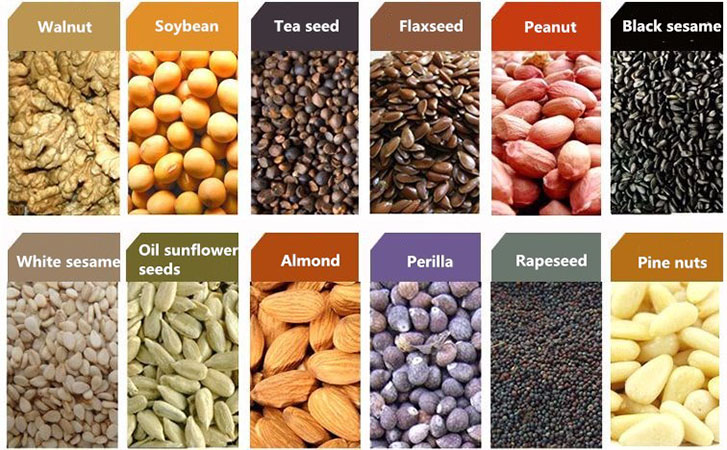

suitable to all kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Raw material

It can be used for oil extraction from peanut kernel, sunflower seed kernel,cotton seed, soybeans, rapeseed,safflower seed,castor seed and other oil crops.

Working priciple

Working priciple

(1)P-acid degumming operation:Drawing the filtered or settled crude oilinto the neutral pot, control oil temperature 40 ° C, liquidlevel cover theneutral pot volume about 80 %.Add into theneutral pot Pacid with 85% concentration, 0.1-0.2% oil weight.Start up neutral pot, make main shalf stirring at 60-70 r/min, finish de-gumming in 30 min.Adjust the neutral pot oil temp to about 85 °C, add into hot water whose temp higher oil temp 10-15° C, the water use amount each time is 10-15% oil weight.(2)alkali de-acid operationAfter finish degumming process, at once add into lye carrying alkali refining deacid, lye concentration 16 ° Be ′, super alkali is 0.1to0.3% oil weight, after finish adding, continuous stirring 30min, when soap particles accumulated condensing, should reduce stirring speed, 30r/min avoid emulsion. After adding alkali, gradually rising temp to the end temp 65 ° C, see to that the rising temp speed should control at 1 degree per minute, not too fast. Shut off neutral pot drive part, theoil settled in the pot 6-8 hours, make oilseparate from soap.(3)de-coloring:Pump the oil netralized into decolorizer vessel , samely mixing to rise its temperature to 90 degrees,then mixing for 30 mins,to reduce water to 0.1% ,then put a little clay (decoloring media) 24 % of total oil ,mixing for 30 mins ,to reduce the temperature to 70 degrees, then filte the clay with oil filter,to get the oil decolorized .

Advantage

1. It is easy for people to learn, understand, and operate because of its small size. Besides, it is no special requirements for people to operate.2. It costs less various expenses with lower electricity consumption in use.3. The machine is a hydraulic machine with big pressure, high oil yielding rate and pure oil Quality.4. The machine adopts automatic control system, automatic preheating control and automatic pressure control of hydraulic system.

Product Specification

Product Specification

| Model | ZY-80 | ZY-100 | ZY-125 | ZY-150 | |

| Power | Power | 5.5kw | 7.5kw | 15kw | 22kw |

| Pump | 1.1kw | 1.1kw | 1.5kw | 2.5kw | |

|

Heater |

2KW | 2.2kw | 2.8kw | 4.5kw | |

| Capacity | 80-130kg/h | 140-280kg/h | 350-400kg/h | 350-450kg/h | |

| Weight | 780kg | 1100kg | 1500kg | 1500kg | |

| Dimension(mm) | 1700*1200*1500 | 1800*1300*1680 | 2100*1400*1700 | 2500*1750*2000 |

Company Profile

We are engaged in food grain and oil engineering design, new technology development, machinery and equipment manufacturing, engineering, installation and commissioning of the entire training services in one of the professional engineering company.Company institutions are: engineering technology, marketing services, integrated management of the Ministry of Finance Management Department, machinery manufacturing center and research and development centers and other departments. Including engineering and technical design staff of nearly 20 people, designed to work in all computer operations, forming a set of scientific research, production and development as one of scientific research and development based engineering company.Our project covering more than 20 domestic provinces, municipalities and autonomous regions, and exports of South Africa, Ethiopia, South Asia, Pakistan, Russia and dozens of countries, the company manufacturing may bear 2000t / d pre-crushing and leaching, 600t / d refinery and other large equipment and engineering installation and commissioning.Companies adhere to the “credibility of the first, leading technology” business philosophy, and gradually formed a service-oriented corporate culture. Adhere to high standards, to provide customers with high quality personalized service.

Service

1.We are resonsible for installation and debugging; 2.Instruct operation workers about the operation skills and offer technical service. 3.Quality warranty of the whole set of equipment is offered;

FAQ

Q1: What is the Material?A1: Stainless steel or carbon steel.Q2: When can I get the price?A2: Within 24 hours, if urgent, please directly call us.Q3: Whether the machine price can be more discount?A3: In general, our MOQ is 1set with very reasonable price, but if large order, we also can apply to our Manager to appropriatelygive you a little discount.Q4: How to ask quotation?A4: Please note us what tpye of raw seeds , and how many tons of raw seeds you want to treat per day, then we will send youquotation as soon as we can.Q5:Does the screw oil press need to be heated?A5:Yes, it does. Preheat with dry oil cake for 30 minutes before feeding seeds normally.Q6: How many people are required to operate this screw oil press?A6: 1-2 people can operate.