Applicable Industries:Manufacturing Plant

Showroom Location:None

Condition:New

Application:Chemical, Commodity, Food, MEDICAL

Packaging Type:CANS

Packaging Material:Metal

Automatic Grade:Automatic

Driven Type:Pneumatic

Voltage:220V/380V

Place of Origin:Jiangsu, China

Brand Name:MEITAR

Dimension(L*W*H):2200X2100X2200MM

Weight:2500 KG

Warranty:1 Year

Key Selling Points:Easy to Operate

Machinery Capacity:2400-3600BPH

Filling Material:Oil, Liquid

Filling Accuracy:≤±1%

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, PLC

After-sales Service Provided:Engineers available to service machinery overseas

Product name:aerosol can filling machine line

Filling speed:2400-3600cans/H

Liquid Filling volume:10-750ml

Gas filling volume:10-750ml

Filling accurancy:≤±1%

Air consumption:3-5m3/min

Certification:ISO9001:2000

Factory Directly Sale Automatic Aerosol Spray Can Filling Machine Line For Spray Paint

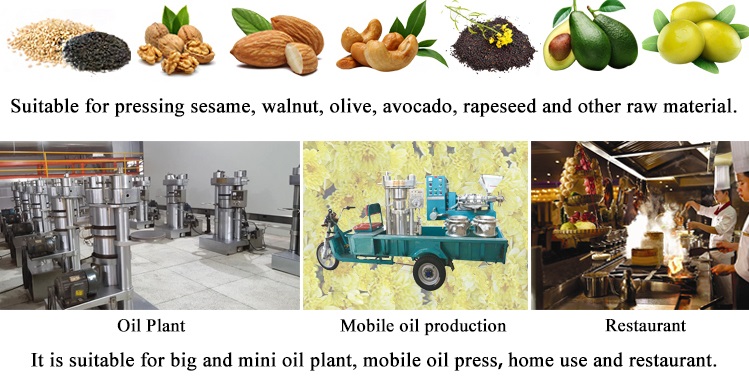

Raw materials:It is suitable to kinds of raw materials , such as sesame, sunflower seeds, soybean, peanut, coconut, etc

Raw material

This small screw press is an advanced oil press, which has the characteristics of high oil yield, good quality, simple design and continuous operation. Oil press can be used for more than 20 kinds of raw materials, such as sesame, walnut, rapeseed, sunflower, soybean, castor seed, pumpkin seed, sauna seed, almond, nut, hazelnut, coconut seed, etc.

Working priciple

Working priciple

Operate Processing Of The Automatic Oil Press Machine:1.stir-fring the seed2.feed in the oil seed3.pressing the seed in the pressing chest4.oil drip on the oil pan from the squeezing bolt5.then oil inflow the vacuum oil filter pan by the vacuum system6.then pure oil come out of the filter7.ready

Advantage

1.small area covering, easy to install and operate, no special requirement for operators.2. Low power consumption, and low cost.3. Belongs to hydraulic equipment, high pressure, high oil yield, high oil quality.4. Full automatic control system. Preheat temperature is self controlled , and so is the hydraulic pressure system.

Product Specification

Product Specification

| Model | 6YL-80 | 6YL-100 | 6YL-120 | 6YL-130 | 6YL-160 |

| Screw speed | 30-45r/min | 30-40 r/min | 30-40 r/min | 28-40 r/min | 28-40 r/min |

| Gear Ratio | 14/42×19/57=1:6.63 | 15/40×15/55=1:9.78 | 15/34×15/55=1:9.59 | 15/38×19/48=1:7.38 | 15/38×15/52=1:8.78 |

| Dimension | 1700*1300*1750mm | 2100*1360*1950mm | 2050x1350x2000mm | 2400x2300x1700mm | 2500x1600x2500mm |

| Productivity | 80-150kg/h | 150-250kg/h | 200-300kg/h | 250-400kg/h | 450-600kg/h |

| Power | 6-5.5KW | 6-7.5KW | 6-11KW | 6-15KW | 6-18.5KW |

| Vacuum pump | Y90S-4-0.55KW | Y90S-4-1.1KW | Y100L1-4-1.5KW | Y100L1-4-2.2KW | Y100L1-4-2.2KW |

| Heater | 2KW | 3KW | 3.3KW | 3.8KW | 4KW |

Company Profile

We are a comprehensive enterprise integrating R&D, production and sales. The existing standardized production workshop covers an area of 5,000 square meters, and it has established a mechanical equipment exhibition hall of 2,000 square meters.The company has always been market demand-oriented. The company has a complete design, production, sales and perfect after-sales service system to provide you with high-efficiency, energy-saving and environmentally friendly mechanical products and processes. The company has a research and development department that can provide you with customized services in addition to standard products.The company relies on scientific management system, high-quality products, good sales and full-process technical services, and has been widely praised by customers. The needs of customers are our way forward, and we look forward to cooperating with you!

Service

Pre-sale services1) Selecting equipment type;2) Designing and fabricating the products in accordance with the special requirements of the clients;3) Training technical personnel for our clients;4) Providing construction and technology consultations or working out proper construction schemes for those new, special or difficult projects.After-sale services1) Assisting the clients preparing for the first construction scheme;2) Installing and testing the equipment;3) Training the first-line operators on site;4)Supplying spare parts with cost.

FAQ

1. Q: Which kind of materials can be process?A: All kinds of oil seeds, including common oil material:soybean, rice bran, corn germ, cottonseeds, peanut, sunflower, rapeseed, palm fruit etc from the pre-treatment,pressing,solvent extraction and refining plant.2. Q: What’s the production capacity can you process?A: 3-5000 tons per day. 3.Q: How long is your guarantee ?A: One Year guarantee. Supply free exchange for spare parts. After this period, we shall charge at low cost to keep after service. You will be welcome to contact us with any problem might occurred.4.Q: How is the quality of your products ?