Showroom Location:India, None

Condition:New

Usage:Mustard Oil

Type:Cold & Hot Pressing Machine

Automatic Grade:Semi-automatic

Production Capacity:30 ton/day

Place of Origin:Punjab, India

Brand Name:GOYUM

Voltage:220V/380V/440V

Dimension(L*W*H):Customised

Weight: KG

Warranty:One Year warranty against manufacturer defect.

Key Selling Points:High Productivity

Marketing Type:Hot Product 2019

Machinery Test Report:Provided

Video outgoing-inspection:Not Available

Warranty of core components:1 Year

Core Components:Gearbox

Oil type:Flax Seed Oil, Soybean Oil, Rap seed oil, Tea Seed Oil, Basil oil, SESAME OIL, Pinenut oil, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, OLIVE OIL, Palm Oil

Max Capacity:1250 kg/h

After-sales Service Provided:Engineers available to service machinery overseas

complete Warranty Service:Video technical support

After Warranty Service:Spare parts

On site Warranty Service:Field maintenance and repair service

Raw material:Oil Seeds

Function:Making Edible Oil

Product name:Oli Press Machine

Application:Edible Oil Production

Keyword:Oil Expeller

Used for:Edible Oil Making

Automatic screw press oil expeller machine with round kettle

Suitable for sunflower seeds, rapeseed, oleander, soybean, tea seed, pepper seed, sesame, peanut.

Raw material

Raw materials:It is suitable to kinds of raw materials , such as sesame, sunflower seeds, soybean, peanut, coconut, etc

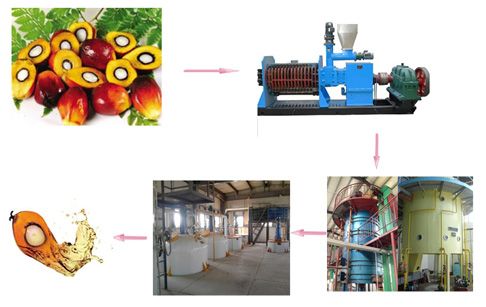

Working priciple

Working priciple

(1)P-acid degumming operation:Drawing the filtered or settled crude oilinto the neutral pot, control oil temperature 40 ° C, liquidlevel cover theneutral pot volume about 80 %.Add into theneutral pot Pacid with 85% concentration, 0.1-0.2% oil weight.Start up neutral pot, make main shalf stirring at 60-70 r/min, finish de-gumming in 30 min.Adjust the neutral pot oil temp to about 85 °C, add into hot water whose temp higher oil temp 10-15° C, the water use amount each time is 10-15% oil weight.(2)alkali de-acid operationAfter finish degumming process, at once add into lye carrying alkali refining deacid, lye concentration 16 ° Be ′, super alkali is 0.1to0.3% oil weight, after finish adding, continuous stirring 30min, when soap particles accumulated condensing, should reduce stirring speed, 30r/min avoid emulsion. After adding alkali, gradually rising temp to the end temp 65 ° C, see to that the rising temp speed should control at 1 degree per minute, not too fast. Shut off neutral pot drive part, theoil settled in the pot 6-8 hours, make oilseparate from soap.(3)de-coloring:Pump the oil netralized into decolorizer vessel , samely mixing to rise its temperature to 90 degrees,then mixing for 30 mins,to reduce water to 0.1% ,then put a little clay (decoloring media) 24 % of total oil ,mixing for 30 mins ,to reduce the temperature to 70 degrees, then filte the clay with oil filter,to get the oil decolorized .

Advantage

1.High rate of oil yield: directional pressure,multi-step impelling,complete pressing once only.2.High output: strengthened feeding system,fast process,high efficiency.3.Automatic temperature control: electric program control,scientific heating, and automatic control of temperature.4.Automatic oil filtration: under the principle of negative pressure of air,vacuum diverter is adopted for effective separation of oil and residue.5.Safe and convenient: compact structure,small floor space;the transmission system adopts closed protection.6.Beautiful: the machine is coated with the latest material through static electricity,with strong adhesion and grease and high temperature resistance. It’s beautiful and easy to clean.7.Durable: High quality wear-resistant steel and anti-fatigue castings ensure stable performance and long-term continuous work.

Product Specification

Product Specification

| Model | ZY-80 | ZY-100 | ZY-125 | ZY-150 | |

| Power | Power | 5.5kw | 7.5kw | 15kw | 22kw |

| Pump | 1.1kw | 1.1kw | 1.5kw | 2.5kw | |

|

Heater |

2KW | 2.2kw | 2.8kw | 4.5kw | |

| Capacity | 80-130kg/h | 140-280kg/h | 350-400kg/h | 350-450kg/h | |

| Weight | 780kg | 1100kg | 1500kg | 1500kg | |

| Dimension(mm) | 1700*1200*1500 | 1800*1300*1680 | 2100*1400*1700 | 2500*1750*2000 |

Company Profile

We are a Professional and modern grain and oil machinery engineering equipment manufacturer integrating research, manufacturing and installation. We have obtained rich experience and practice in palm fruit oil machine, vegetable oil pretreatment, prepress,extraction, sophisticated technology and equipment designs etc, owing wide international market in more than 130 countries and regions.With more than 30 years of experience on oil making machine, we provide a comprehensive range of products We are proud to guarantee that, with our strong technical background and communication capability, our sales/support engineers are able to answer your most complicated technical questions over the phone in English. That would save a lot of time for communication.The following pictures show our company and customers in our workshop.

Service

1. We are the true manufacturer of the oil pressing machine2. Free spare parts to be delivered with our machine3. Professional technical support for our customers at 24/7

FAQ

1.Q: What’s the payment terms?A: T/T,Trade Assurance,Western Union, MoneyGram,L/C, Cash etc.2.Q: What kind of seeds that the machine can press?A:The cold press oil machine can press the peanuts,sunflower,ricino,coconut, almond, canola seed,walnut, copra,palm kernels, rapeseed, flaxseed,coconut, cotton seeds, sesame,soybeans,flax seed,etc.