Max.Bottle Height(mm):330 mm

Neck Diameter(mm):100 mm

Max.Bottle Diameter(mm):105 mm

Bottle Volume(ml):2000 ml

Condition:New

Application:bottle

Blow Moulding Type:Stretch Blow Moulding

Place of Origin:China

Brand Name:WATON

Voltage:Customized

Dimension(L*W*H):168*65*175

Hollow part volume:50~2000 ml

High Pressure Valve Brand:AirTac

PLC Brand:MITSUBISHI

Power (kW):14

Weight (KG):1200 KG

Automation:Semi-automatic

Warranty:2 years

Key Selling Points:Easy to Operate

Showroom Location:Peru, Saudi Arabia, Spain, Turkey, France, Russia, Italy, Thailand, Mexico, India, Viet Nam, Canada, United States, Brazil, United Kingdom, Indonesia, Germany, Egypt, Philippines, South Korea, Algeria, Chile, UAE, Japan, Uzbekistan, Nigeria, Argentina, Romania, Australia, Ukraine, Kyrgyzstan, Malaysia, Kazakhstan, Tajikistan, Bangladesh, Kenya, South Africa, Colombia, Morocco, Sri Lanka

Applicable Industries:Food & Beverage Factory

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:2 years

Core Components:Bearing, Motor, Pump, Gear, PLC, Other, Pressure vessel, Engine, Gearbox

Model Number:MS-10L

Suitable bottle:Water bottle/juice bottle/drink bottle/oil bottle

Advantages:cheap, wide application

Machine color:Custom-made

Machine capacity:700-1000BPH

Bottle capacity:2000ml

Mold cavity:2

Bottle Max Diameter:100mm

Bottle Max Height:350mm

OEM/ODM service:Yes

NEW MS-10L Cheap Price PET Blow Molding Machine Water Bottle 400BPH Semi Auto Blowing Machine

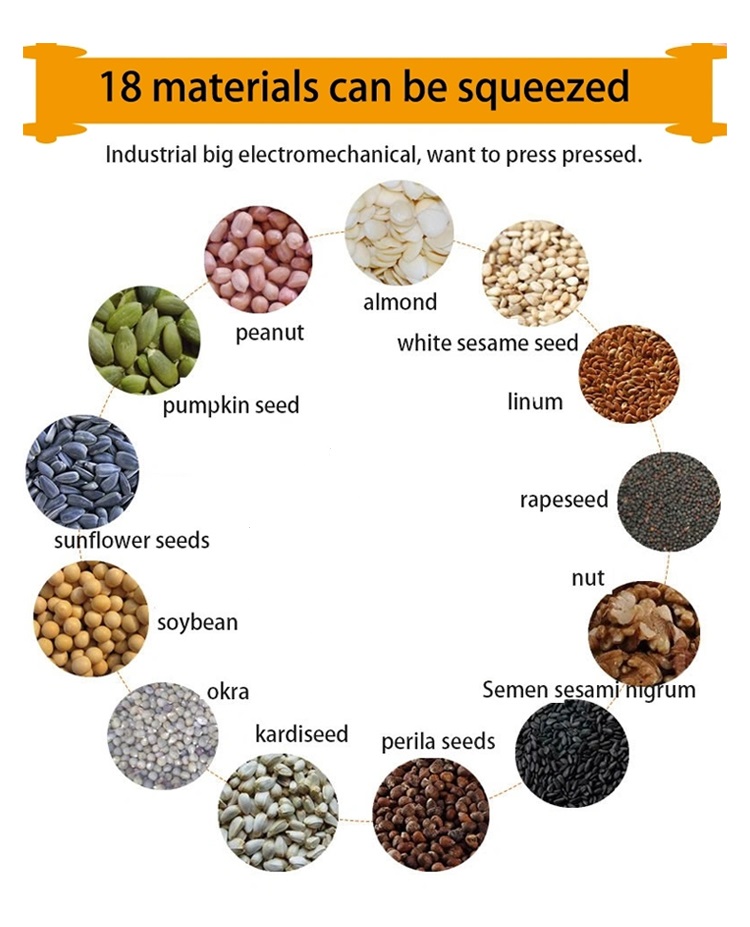

The Oil press is used to get the edible oil from vegetable oil seed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, sesame seed, cottonseed, coconut, etc. This presser can press up to 5 ton raw material per day.

Raw material

Hot and cold automatic modern oil press is a new product developed by our company. It can press rapeseed, peanuts, tea seed, soybean, sesame, sunflower and other oilseeds, the machine is equipped with micro electric control, infrared heating, filtration system, multistage press.

Working priciple

Working priciple

The technology flow of cooking oil solvent extraction machine:The process is like oil extracted – wet meal desolvation – mixed oil vaporation – stripping by steam – solvent recoveryMaterial embryos→Extraction→Wet meal→Evaporation→Cooling→Product meal packing ↓Mixed oil→Filter→Negative pressure evaporation → Crude oil ↓Solvent recovery

Advantage

(1) High oil yield , obvious economic benefit.(2)Residual oil rate in the dry meal is low.(3)Improving the quality of the meal and oil.(4)Low processing cost , high labor productivity.(5)High automatic and labor saving.And more other advantages please contact me now,we will provide profession program for you,and we accept custom according your requirements.

Product Specification

Product Specification

| Oilseeds | Processing Capacity (kg/h) | |

| 95DFY | 110JDFY | |

| rapeseed | 150-220 | 250-300 |

| cottonseed | 150-220 | 250-300 |

| soybean | 140-340 | 230-270 |

| peanut | 150-220 | 250-300 |

| Oil efficiencies(%) | ≥95% | ≥94% |

| Motor for pressing(kw) | 11(380V) | |

| Motor for oil filtering(kw) | 3(380V) |

Company Profile

We are engaged in food grain and oil engineering design, new technology development, machinery and equipment manufacturing, engineering, installation and commissioning of the entire training services in one of the professional engineering company.Company institutions are: engineering technology, marketing services, integrated management of the Ministry of Finance Management Department, machinery manufacturing center and research and development centers and other departments. Including engineering and technical design staff of nearly 20 people, designed to work in all computer operations, forming a set of scientific research, production and development as one of scientific research and development based engineering company.Our project covering more than 20 domestic provinces, municipalities and autonomous regions, and exports of South Africa, Ethiopia, South Asia, Pakistan, Russia and dozens of countries, the company manufacturing may bear 2000t / d pre-crushing and leaching, 600t / d refinery and other large equipment and engineering installation and commissioning.Companies adhere to the “credibility of the first, leading technology” business philosophy, and gradually formed a service-oriented corporate culture. Adhere to high standards, to provide customers with high quality personalized service.

Service

For warranty parts and service:**1 year warranty.**Within warranty period, all exchanges due to defects are free (Buyer is responsible for shipping charges).** Within warranty period, As to after-sales service, all the freight fare and accommodation will be paid by buyer

FAQ

1.Q:Can you guarantee the quality of your machine?A:We are a professional manufacturer with strict quality requirementsoil press machine2.Q:Does your factory accept customization?A:As a professional manufacturer, we can do almost any kind of customization.3.Q:What’s the delivery time?A:Generally after paying the final payment 3-5 days.4.Q:How long can I receive the goods after placing the order?A:7-15 days if there is no unexpected.5.Q:What should I do if the oil making machine will not be installed?A:Don’t worry, we have a perfect after-sales service system and can provide you video supports for free.6.Q:What’s your terms of payment?A:50% in advance, balance before shipment.