Showroom Location:None

Condition:New

Usage:Peanut Oil

Type:Cold & Hot Pressing Machine

Automatic Grade:Manual

Production Capacity:depends on you

Place of Origin:Henan, China

Brand Name:zzKnown

Voltage:manual

Dimension(L*W*H):350*60*316.5mm

Weight:3kg

Warranty:1 Year

Key Selling Points:Multifunctional

Marketing Type:New Product 2020

Machinery Test Report:Not Available

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Engine

name:mini oil press

color:red or at your request

size:350*60*316.5mm

weight:3KG

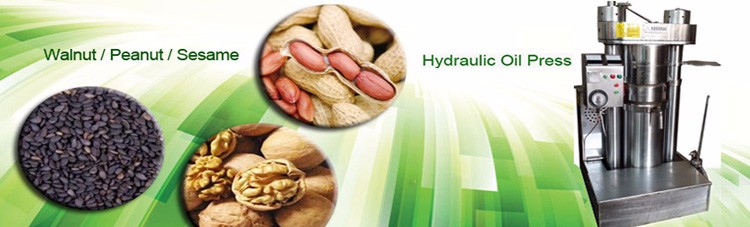

material:peanut,sesame,sunflower,soybean ,walnut ,etc

power:manual

main parts:frame,press cage,screw shaft,crank ,etc

certificate:CE,ISO

Feature:Oil Processing Equipment

Whatsapp:+86-17734784788

After Warranty Service:Video technical support, Online support

Local Service Location:None

After-sales Service Provided:Online support

Certification:CE,ISO

2022 Easy Operation Mini Oil Press Machine Manual Cold Press Machine Coconut Oil Manual Expeller Making Maker

Raw materials:It is suitable to kinds of raw materials , such as sesame, sunflower seeds, soybean, peanut, coconut, etc

Raw material

Automatic oil machine is suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame seed, tea seed, walnut, olive, corn germ, rice bran, safflower seed, seeds of hippophae rhamnoides and so on.

Working priciple

Working priciple

Oil solvent extraction section of vegetable oil production line:Cooking oil solvent extraction machine mainly include oil extraction system, desolventizing and toasting system, evaporation system and condensation system. Main theory is to use appropriate solvent extract oil from oilseeds embryo, then remove the solvent in mixed oil. Our oil extraction process technology to produce mixed oil without any chemical solvents, and can remove the tail gas directly, benefits environment protection.

Advantage

● Well-adapted: without pressure to handle multi-material processing. Such as peanut, soybean, sesame, sunflower seed, rapeseed, mustard, copra.castor bean ● Less investment: especially suitable for start-up companies and those investors who don’t want to invest too much in the first time. Efficiently profit, short-term return. ● Smooth transmission: slight vibrating in the process of operation, much more durable; no oil and cake scattering, good oil collection, protect environment of workshop at the same time.

Product Specification

Product Specification

| Model | ZY-80 | ZY-100 | ZY-125 | ZY-150 | |

| Power | Power | 5.5kw | 7.5kw | 15kw | 22kw |

| Pump | 1.1kw | 1.1kw | 1.5kw | 2.5kw | |

|

Heater |

2KW | 2.2kw | 2.8kw | 4.5kw | |

| Capacity | 80-130kg/h | 140-280kg/h | 350-400kg/h | 350-450kg/h | |

| Weight | 780kg | 1100kg | 1500kg | 1500kg | |

| Dimension(mm) | 1700*1200*1500 | 1800*1300*1680 | 2100*1400*1700 | 2500*1750*2000 |

Company Profile

We have 8 standard production workshops, 2 machining workshops and 12 engineering installation teams. Huatai Machinery Company has 120 sets of processing equipment, including more than 80 sets of lathes, planers, milling machines and drilling machines,over 10 sets of shears forming equipment, 6 sets of submerged arc automatic welding machines, more than 80 sets of welding machines , and also equipped with various auxiliary equipment and detection equipment.Our oil making machine sells well in more than 30 provinces,cities and districts, and are exported to Russia,Malaysia,Kazakhstan,Thailand, Indonesia,Egypt, Philippines Russia,Kazakhstan,Uzbekistan,Tajikistan, Bolivia, Peru, Indonesia and other countries & regions,and now we have developed into a major oil machinery manufacturing.

Service

We always put the interests and quality of its clients first, insists the principle that there is no best but only better service. We will commit to provide quality products and improve on-site service and service after selling. Specific commitments are now as follows:We will organize an experienced engineering team, managed by the Project Manager.Ensure high-quality materials, excellent service provided to the user;During the installation process, we will appoint a technical and installation supervision services at the scene.We do debugging of stand-alone equipment and on-line debugging and commissioning test run to ensure normal operation of the project at full load conditions.Supply the technical of your staff to ensure training of personnel to operate independently for free.To ensure that once installation acceptance; Within one month, to provide customers with qualified acceptance after completion of archive.To ensure timely provision of equipment and accessories;We have developed new products, new technology, will give priority to customers;In the equipment’s warranty period (within 12 months of the date of commissioning qualified):Due to the quality of the equipment itself damage, we will repair or replace parts.Damage due to customer reasons, only charge the material cost for repair or replacement by the buyer. After the customer informed our company, we will put forward a propose within 24 hours, using the fastest way to resolve the issue the required components.We are willing to supply good service on your business development.

FAQ

Q1: Why choose us? A: We are a factory, not just a trading company. It has its own independent research and development team and production workshop,inspection and quality control procedures to ensure that each purchased product meets global quality standards. Custom services are also available Q2: What about your warranty? A: Our warranty is 1 year. Q3: Is there anyinstallation direction after we received the machine? A: Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.